English Documentary on Plastics with Transcript and illustrated flashcards to improve your listening and reading comprehension and expand your vocabulary

Source of documentary: National Geographic YouTube Channel

Plastics

Plastics have become such an entrenched part of our lives, but what exactly is plastic and how is it made? Before plastic became so ubiquitous, it underwent a transformation from being a strictly natural product to being synthetically and widely produced.

Earliest uses of plastic

Some of the earliest uses of plastic date as far back as 3,500 years ago when the Olmecs of Mexico used naturally occurring plastics, sap from gum trees to create rubber balls. During the mid-19th and 20th centuries, synthetic plastics like celluloid and Bakelite, made their debut and were used for decades.

Structure of plastics

On the molecular level, plastics are made of polymers which are long flexible chains of chemical compounds. This structure allows plastics to be easily molded and shaped, especially under heat and pressure. Unlike the rubber used by the Olmecs, most of today’s plastics are manmade and derived from fossil fuels. Crude oil and natural gas are primarily sources as they provide a cheap alternative to plastic made from plants.

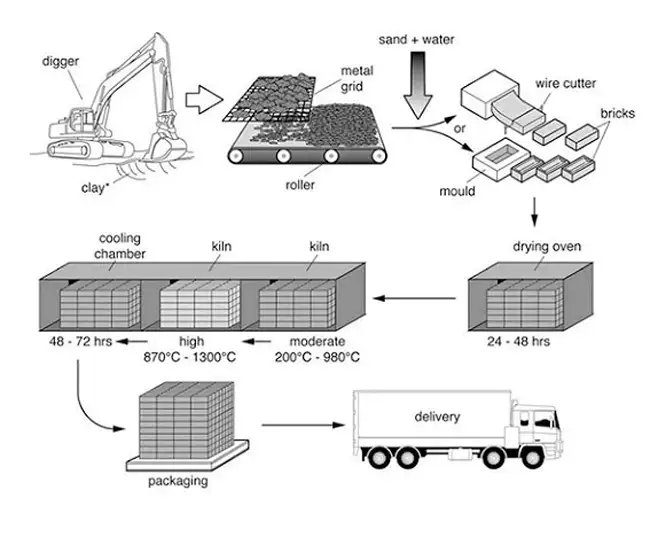

Steps in the production of plastic

The first step in the production of plastic is the extraction of crude oil and natural gas from the ground. From there, the fossil fuels are sent to refineries where they are converted into several products including the building blocks of plastic, ethane from crude oil and propane from natural gas.

Ethane and propane are then sent to a cracker plant to be cracked or broken down into smaller molecules. Ethane produces ethylene and propane becomes propylene. Next, a catalyst is mixed in which links the molecules together and forms polymers called resins. This structure allows plastics to be easily molded and shaped, especially under heat and pressure. Polymerization converts ethylene into the resin, polyethylene, and propylene into polypropylene.

These resins are then melted, cooled down and chopped up into preproduction plastic pellets known as nurdles. Nurdles are later transported to manufacturers who use heat to mold the nurdles into different types of plastic products.

Resin identification codes

Many of those products actually feature information about their manufacturing process. Numbers called resin identification codes are often featured indicating which chemicals were used to make the plastic.

World plastic production

Because of plastics utility, its global production has doubled about every decade. The amount of plastics produced since 1950 has measured at about 9.2 billion tons, the weight of nearly 1600 Great Pyramids of Giza.

Plastics are not environmentally friendly

Much of this plastic ends up as trash. Single-use plastics such as straws, grocery bags and packaging products are particularly detrimental. They often aren’t recycled and constitute about 40% of all plastic waste. They end up damaging natural habitats, endangering wildlife, and polluting communities around the world.

Simple measures to reduce plastic pollution

Moving forward, a great way we can counter this plastic pollution is to reduce the amount of single-use plastics we use. By opting, instead, for reusable alternatives in our day-to-day lives, each person can make a huge impact in helping decrease plastic waste.

Recycling old plastics

For plastics that are already produced, other solutions are being explored. Scientists have discovered that a few organisms are capable of breaking down plastic material. Wax worms and mealworms, for example, can devour plastics and turn them into compost. Another plastic-consuming organism is a microbe which shrinks the time plastic takes to degrade from hundreds of years to only a few days.

Modern technology to produce plastics

Change is happening in the production of plastics as well with some manufacturers turning back to plants for ingredients. Called biodegradable bioplastics, these materials are as durable as synthetic plastics, come from renewable resources and can therefore, biodegrade. Even the rubber tree, the same plant used by the Olmecs, is once again being sourced for plastic.

Today, the trees latex is used to create a range of products such as all-natural latex rubber gloves, tires, and mattresses. The rubber tree itself is now part of a global initiative for the natural and sustainable sourcing of plastic.

Plastics can be found almost anywhere, but by understanding its chemical makeup and our uses for it, we can benefit from its versatility while also being mindful of its impact on our planet.

Plastics could be usefull but really dangerous. A little Plastic in the ocean could kill so many poor fishes. And they say that fishes well be a rare thing to find in the ocean just in few years later. We should try other things to save the planet from this huge mess.

That was a great comment! Thank you.

Feedback

1. usefull = useful

2. fishes = fish (plural noun)

2. well vs. will

It is true that plastic is not environmentally friendly and its waste and usage are becoming increasingly dangerous. However, we cannot completely eliminate our reliance on plastic. Therefore, the better solution is to learn how to recycle and reduce our daily use of plastic.

That’s a great solution you’ve offered! Suitable use of plastics and recycling the goods made of them must be taken into account to deal with the dire consequences and detrimental effects of the earth replete with unrecycled plastics.

Plastic

Plastics have become such an entrenched part of our lives, but what exactly is plastic and how is it made?

Before plastic become so ubiquitous, it underwent a transformation from being a strictly natural product to being synthetically and widely produced.

* Earliest uses of plastic:

Some of the earliest uses of plastic data as far back as 3500 years ago when the Olmecs of Mexico used naturally occurring plastics, sap from gum trees to create rubber balls. During the mid-19th and 20th centuries, synthetic plastics like celluloid and Bakelite, made their debut and were used for decades.

On the molecular level, plastics are made of polymers which are long flexible chains of chemical compounds. This structure allows plastics to be easily molded and shaped, especially under heat and pressure.

Unlike the rubber used by the Olmecs, most of today’s plastics are manmade and derived from fossil fuels. Crude oil and natural gas are primarily sources as they provide a cheap alternative to plastic made from plants.

* Steps in the production of plastic

1. Extraction: The first step in the production of plastic is the extraction of crude oil and natural gas from the ground.

2. Refinement: From there, the fossil fuels are sent to refineries where they are converted into several products including the building blocks of plastic, ethane from crude oil and propane from natural gas.

3. Cracking: Ethane and propane are then sent to a cracker plant to be cracked or broken down into smaller molecules. Ethane produces ethylene and propane becomes propylene.

4. Polymerization: Next, a catalyst is mixed in which links the molecules together and forms polymers called resins. This structure allows plastics to be easily molded and shaped, especially under heat and pressure. Polymerization converts ethylene into the resin, polyethylene, and propylene into polypropylene.

These resins are then melted, cooled down and chopped up into preproduction plastic pellets known as nurdles. Nurdles are later transported to manufacturers who use heat to mold the nurdles into different types of plastic products.

* Resin identification codes

Many of those products actually feature information about their manufacturing process. Numbers called resin identification codes are often featured indicating which chemicals were used to make the plastic.

* World plastic production

Because of plastics utility, its global production has doubled about every decade. The amount of plastics produced since 1950 has measured at about 9.2 billion tons, the weight of nearly 1600 Great Pyramids of Giza. Much of this plastic ends up as trash. Single-use plastics such as straws, grocery bags and packaging products are particularly detrimental. They often are not recycled and constituted about 40% of all plastic waste.

The end up damaging natural habitats, endangering wildlife, and polluting communities around the world.

* Simple changes for reduce plastics pollution

1. Moving forward, a great way we can counter this plastic pollution is to reduce the amount of single-use plastic we use. By opting, instead, for reusable alternatives in our day-to-day lives, each person can make a huge impact in helping decrease plastic waste.

2. Organisms that break down plastic: For plastics that are already produced other solutions are being explored. Scientists have discovered that a few organisms are capable of breaking down plastic material. Wax worms and mealworms, for example, can devour plastics and turn them into compost. Another plastic-consuming organism is a microbe which shrinks the time plastic takes to degrade from hundreds of years to only a few days.

3. Change is happening in the production of plastics as well with some manufacturers turning back to plants for ingredients, called biodegradable bioplastics, these materials are as durable as synthetic plastics, come from renewable resources and can therefore, biodegrade.

4. Even the rubber tree, the same plant used by the Olmecs, is once again being sourced for plastic. Today, the trees latex is used to create a range of products such as all-natural latex rubber gloves, tires, and mattresses. The rubber tree itself is now part of a global initiative for the natural and sustainable sourcing of plastic.

Plastics can be found almost anywhere but by understanding its chemical makeup and our uses for it, we can benefit from its variety while also being mindful of its impact on our planet.

Take your pledge today to reduce single-use plastics.

Thank you so much for your almost accurate transcription, which was rather too long, with the following errors listed in order:

1. before plastic became so

2. date as 3,500 (not data)

3. constitute about 40%

4. the end up –> they end up

5. single-use plastics we use (plural)

6. variety -> versatility